Dunlap Codding is pleased to announce that Marc A. Brockhaus, Emily E. Campbell, Ann M. Robl, Nicholas D. Rouse, Douglas J. Sorocco, and Evan W. Talley have again been selected by attorney peers for inclusion in The Best Lawyers in America® 2024, the oldest and most respected peer–review publication in the legal profession. Shareholder Elizabeth L. Isaac was listed among Ones to Watch as were associates Jeremy McKinney and Andrew P. Piechocki.

Firm managing shareholder Nick Rouse said, “We continue to be proud to stand alongside competitor colleagues among the ranks of those listed in Best Lawyers. We continuously strive to help our clients create and protect robust and strategic intellectual property portfolios, and we are delighted to be recognized for our achievements.”

Dunlap Codding attorneys were recognized in eight intellectual property-related areas of law: Biotechnology and Life Sciences Practice, Copyright Law, Litigation – Intellectual Property, Litigation – Patent, Patent Law, Technology Law, Trade Secrets Law, and Trademark Law.

Marc A. Brockhaus was recognized for five areas: Litigation – Intellectual Property, Patent Law, Technology Law, Trademark Law, and Trade Secrets Laws. Marc leads Dunlap Codding’s Electrical Engineering & Systems group. His practice includes all areas of intellectual property, including technology, computer, and patent law, and extends to counseling, transactions, litigation, and prosecution before the United States Patent and Trademark Office. Mark is ranked in the top band of Oklahoma’s intellectual property practitioners by the highly regarded Chambers USA: America’s Leading Lawyers for Business and is also listed in Super Lawyers 2023 – Oklahoma and as a 2023 IP Star in Managing Intellectual Property. Marc served as an adjunct faculty member at the University of Oklahoma College of Law and received his J.D. and his M.B.A. from the University of Oklahoma in 1997, where he was inducted into Beta Gamma Sigma. He received his B.S. in Electrical Engineering from the University of Oklahoma.

Emily E. Campbell was recognized for Copyright Law and Trademark Law. Emily provides strategic counsel to clients on trademarks, copyrights, Internet law, and licensing. She is ranked in Chambers USA: America’s Leading Lawyers for Business for Intellectual Property Law. Attorney peers also selected her for inclusion in Super Lawyers 2023 – Oklahoma. Emily serves on the University of Oklahoma’s College of Engineering Industrial & Systems Engineering Advisory Board. She received her J.D. from the Oklahoma City University School of Law and received her B.S. in Industrial Engineering from the University of Oklahoma.

Ann M. Robl was selected for Patent Law and Trademark Law. Ann’s work on behalf of clients includes patent preparation, patent prosecution, patent post-grant proceedings, patentability analyses, prior art searching, opinion preparation, licensing, intellectual property agreement preparation and analysis, trademark protection, copyright protection, trade secret management, and intellectual property strategy and portfolio management. Ann’s areas of technical experience include mechanical devices and systems, optics, software-based and computer-based systems, and data transmission and networks. She was previously selected by attorney peers for inclusion in Oklahoma Super Lawyers–Rising Stars Edition. Ann received her J.D. degree from the University of Oklahoma College of Law and her B.S. in Mechanical Engineering, cum laude, from Villanova University.

The publication recognized Nicholas D. Rouse for Patent Law, Technology Law, Trade Secrets Law, and Trademark Law. Nick has served as Dunlap Codding’s managing shareholder since 2007 while continuing an active practice. In its inaugural coverage of intellectual property law in Oklahoma, the highly regarded Chambers USA: America’s Leading Lawyers for Business ranked Nick in the top band of leading practitioners, and he continues to be ranked in the top band. He is also listed as a 2023 IP Star in Managing Intellectual Propertyand was selected for inclusion in Super Lawyers 2023 – Oklahoma. Nick provides a broad range of intellectual property counseling to clients ranging from individual inventors to large multinational manufacturing companies. Nick graduated from the University of Oklahoma with a B.S. in Petroleum Engineering and received his J.D. from the University of Oklahoma College of Law

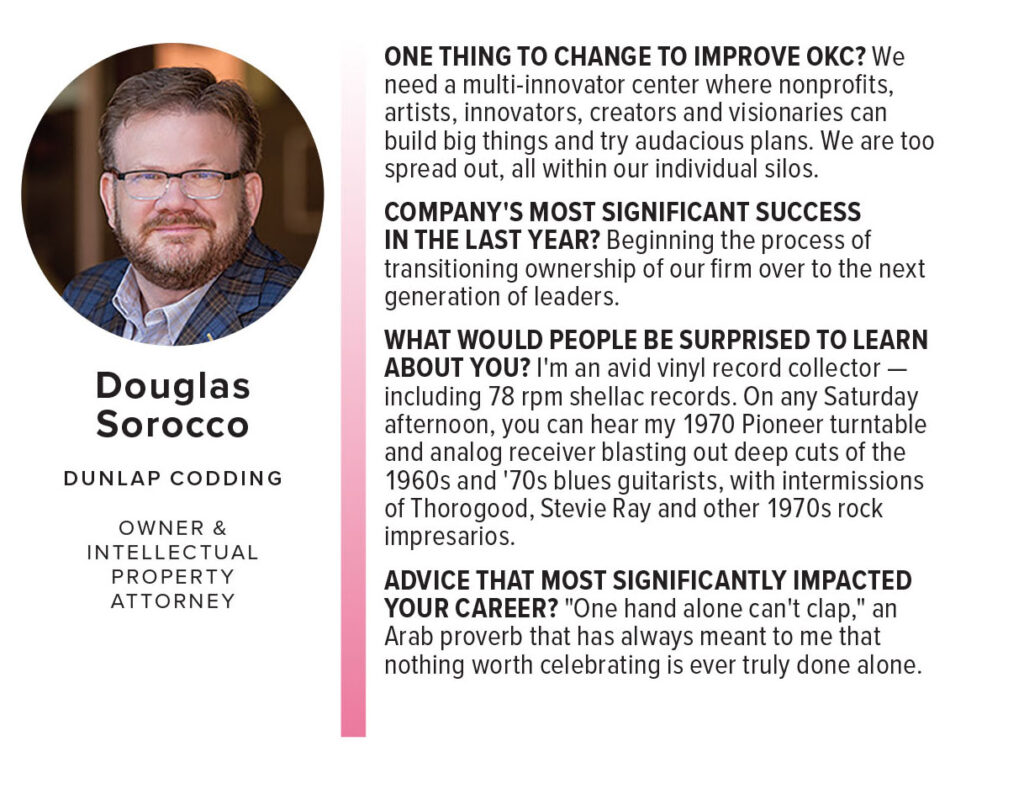

Douglas J. Sorocco was named the 2023 Oklahoma City “Lawyer of the Year –Technology Law.” In the 2024 edition of Best Lawyers, he was also recognizedfor six areas of practice: Biotechnology and Life Sciences Practice, Litigation – Intellectual Property, Litigation – Patent, Patent Law, Technology Law, and Trademark Law. Doug practices in the areas of intellectual property, technology, licensing, life sciences, and patent law and is involved in litigation, counseling, and transactional work involving all aspects of intellectual property, including acquisition and commercialization of intellectual property, portfolio management, and licensing. He is ranked in the top band of Oklahoma’s intellectual property practitioners by the highly regarded Chambers USA: America’s Leading Lawyers for Business and is also listed in Super Lawyers 2023 – Oklahoma. In 2023, he was again selected as an IP Star by Managing Intellectual Property. He is an adjunct faculty member at the Oklahoma City University School of Law and in the Physiology Department at the University of Oklahoma’s Health Sciences Center. Doug received his J.D. from the University of Dayton and his B.S. in Chemistry from Butler University.

Evan W. Talley was recognized for Litigation – Intellectual Property, Litigation – Patent, Trade Secrets Law, and Trademark Law. Evan’s practice focuses on disputes concerning intellectual property rights (patent, trademark, trade dress, copyright, trade secrets, rights of publicity, unfair competition, deceptive trade practices, and artists’ and moral rights) and ranges from pre-litigation dispute resolution through trial and appeal. Evan was selected by attorney peers for inclusion in Oklahoma Super Lawyers–Rising Stars Edition 2019 – 2023. He received his J.D. from the University of Oklahoma College of Law, with Distinction, and was an editor of the American Indian Law Review during law school. Evan received his B.B.A. with Distinction from the University of Oklahoma College of Business.

Barbara Krebs Yuill, Ph.D., was recognized for Patent Law. Barb’s practice also includes trademark, trade secrets, and copyright law. She counsels clients in all aspects of intellectual property, focusing on patent drafting and prosecution, patent infringement and validity opinions, and license preparation and negotiation. Barb has prepared patent applications in the areas of nanoparticle manufacture, treatment and use; methods and compositions for removing planarization and etching residues during semiconductor device fabrication; chemical processing; metallurgical and ceramic materials and manufacture; oil field chemicals and drilling methods; environmental remediation technologies; and mechanical devices for the medical, veterinary and sporting goods industries.

This year, for the fourth time, Best Lawyers selected lawyers with 10 or fewer years in practice as Ones to Watch, honoring three Dunlap Codding attorneys with that distinction.

Elizabeth E. Isaac was selected for Entertainment and Sports Law, Intellectual Property Law, Litigation – Intellectual Property Law, Patent Law, and Technology Law. Elizabeth helps businesses, innovators, entrepreneurs, and artists assess and protect their inventions, brands, designs, and creative works to leverage their intellectual property portfolios and enhance their business options. She counsels clients regarding a breadth of intellectual property with an emphasis on creatively and strategically identifying holistic and dynamic ways to improve the value of various creative and technological assets. Elizabeth was selected by attorney peers for inclusion in Oklahoma Super Lawyers–Rising Stars Edition 2018 – 2023. She received her J.D., summa cum laude, from Oklahoma City University School of Law, and received her B.A., magna cum laude, from Austin College.

Jeremy McKinney was selected for Intellectual Property Law and Patent Law. His practice involves patent drafting and prosecution, licensing, prior art searches, and patentability analysis. Jeremy’s areas of technical focus are electrical, mechanical, and software. He received his J.D. degree from the University of Oklahoma School of Law and his B.S. in Health Science, cum laude, from Trident University International.

Andrew P. Piechocki was selected for Intellectual Property Law, Patent Law, and Technology Law. His practice includes patent drafting and prosecution, licensing, prior art searches, and patentability analysis. His areas of technical focus include electrical engineering and computer science, optics and optical equipment, electronic test equipment, medical devices, software-based and computer-based systems, data transmission and networks, artificial intelligence and machine learning, virtual and augmented reality, and IoT devices. He received his J.D. degree from the University of Tulsa College of Law, his M.S. in Engineering Management from The Catholic University of America, and his B.S., cum laude, in Electrical Engineering from Arkansas Tech University.

Since its inception in 1983, Best Lawyers has become universally regarded as the definitive guide to legal excellence. Because Best Lawyers is based on an exhaustive peer–review survey on the legal abilities of other lawyers in their practice areas, and because lawyers are not required or allowed to pay a fee to be listed, inclusion in Best Lawyers is considered a singular honor. Corporate Counsel magazine has called Best Lawyers “the most respected referral list of attorneys in practice.”

Dunlap Codding, with offices in Austin, Oklahoma City, and Washington, D.C., serves sophisticated international, national, and regional clients. Established in 1957 as Oklahoma’s original intellectual property firm, Dunlap Codding remains the region’s largest and most versatile IP boutique providing counsel in the areas of patent, trademark, copyright, and entertainment law as well as related litigation and licensing services.

CALL

EMAIL

MAP

CALL

EMAIL

MAP

CALL

EMAIL

MAP

Join us on April 27 at 11 a.m. Central for an American Intellectual Property Law Association (AIPLA) Networking Event brought to you by the AIPLA Women in IP Law Committee and local host Dunlap Codding, P.C., located at 609 W. Sheridan Avenue, Oklahoma City.

Join us on April 27 at 11 a.m. Central for an American Intellectual Property Law Association (AIPLA) Networking Event brought to you by the AIPLA Women in IP Law Committee and local host Dunlap Codding, P.C., located at 609 W. Sheridan Avenue, Oklahoma City.